Specification:

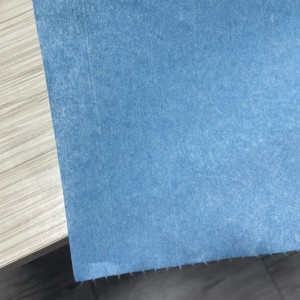

1. Material: Woodpulp+Polyester /Polypropylene/Viscose

2. Basis Weight: 40-110g/m2

3. Width: ≤2600mm

4. Thickness: 0.18-0.35mm

5. Appearance: plain or apertured,patterned

6. Color: white ,colors

Characteristic:

1. Exceptionally clean—containers no binders, chemical residue, contaminants or metal shavings that can result in surface damage or rework

2. Durable—excellent MD and CD strength makes them less likely to snag on mental parts and sharp corners

3. Higher absorbency rate can result in wiping jobs being completed more quickly

4. Low-lint performance helps to minimize defects and contamination

5. Tackles isopropyl alcohol, MEK, MPK, and other aggressive solvents without falling apart

6. Cost-effective —very absorbent ,fewer wipes needed to complete the task results in fewer wipes to dispose of

Application

1.Electronic surface clean

2. Heavy equipment maintenance

3. Surface preparation before coating, sealant, or adhesive application

4. Laboratories and production areas

5. Printing industries

6. Medical use: surgical gown , surgical towel , surgical cover, surgical map and mask , sterile separtion gown, protection gown and bedding clothes.

7. househould wipe

| ITEM | UNIT | BASIS WEIGHT(g/m2) | |||||||

| 40 | 45 | 50 | 55 | 60 | 68 | 80 | |||

| WEIGHT DEVIATION | g | ±2.0 | ±2.5 | ±3.0 | ±3.5 | ||||

| Breaking strength (N/5cm) | MD≥ | N/50mm | 70 | 80 | 90 | 110 | 120 | 160 | 200 |

| CD≥ | 16 | 18 | 25 | 28 | 35 | 50 | 60 | ||

| Breaking elongation (%) | MD≤ | % | 25 | 24 | 25 | 30 | 28 | 35 | 32 |

| CD≤ | 135 | 130 | 120 | 115 | 110 | 110 | 110 | ||

| Thickness | mm | 0.22 | 0.24 | 0.25 | 0.26 | 0.3 | 0.32 | 0.36 | |

| Capacity of liquid-absorbability | % | ≥450 | |||||||

| Speed of absorbability | s | ≤2 | |||||||

| Rewet | % | ≤4 | |||||||

| 1.Based on the comoposition of 55% woodpulp and 45% PET 2.Customers’requirement avaliable |

|||||||||