As sustainability, hygiene, and performance continue to shape material choices across industries, woodpulp spunlace nonwoven fabric has become a widely searched solution among professional buyers. From medical disposables to household wipes, this material combines softness, absorbency, and strength in a way that traditional nonwovens often struggle to achieve.

This article explores what woodpulp spunlace nonwoven fabric is, how it is made, its key advantages, and what B2B buyers should consider when sourcing it.

What Is Woodpulp Spunlace Nonwoven Fabric?

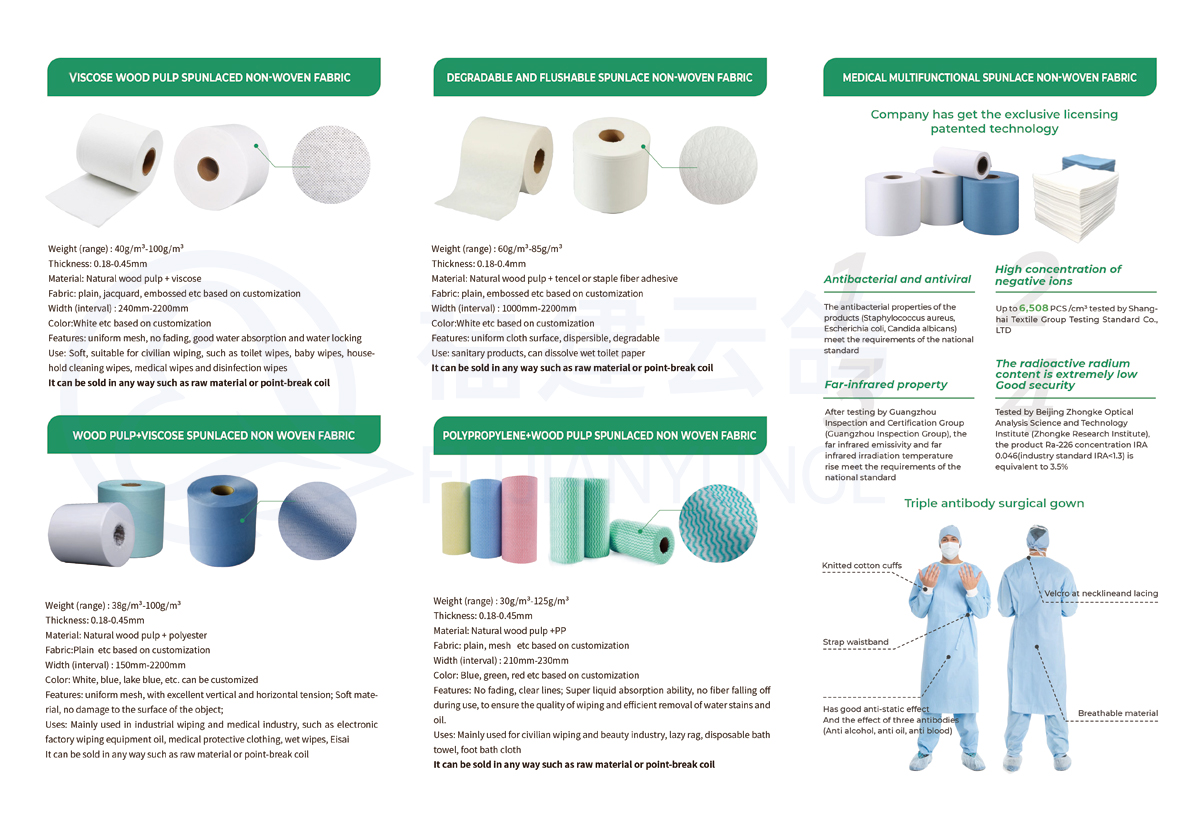

Woodpulp spunlace nonwoven fabric is a hydroentangled nonwoven made by combining natural wood pulp fibers with reinforcing fibers such as viscose or polyester. Instead of chemical binders, high-pressure water jets entangle the fibers, forming a strong and uniform fabric structure.

This production method results in a material that is:

-

1.Soft and cloth-like

-

2.Highly absorbent

-

3.Lint-free

-

4.Suitable for direct skin contact

Because wood pulp is derived from renewable resources, this fabric is often positioned as a more sustainable alternative to purely synthetic nonwovens.

Key Properties That Drive Buyer Demand

Professional buyers searching for woodpulp spunlace fabric suppliers usually focus on performance consistency and application suitability. The most valued properties include:

1. High Absorbency

Wood pulp fibers naturally absorb liquids, making this fabric ideal for wipes, medical consumables, and cleaning applications.

2. Softness and Comfort

The hydroentanglement process preserves fiber integrity, resulting in a smooth surface suitable for sensitive skin and medical use.

3. Excellent Wet Strength

Compared with dry-laid or chemically bonded nonwovens, spunlace maintains structural strength even when wet.

4. Low Linting

This is especially important for cleanroom wipes, medical environments, and precision cleaning.

Common Applications Across Industries

Search trends show that buyers often pair “woodpulp spunlace nonwoven fabric” with specific application terms. The most common use cases include:

-

Medical and healthcare products

Surgical wipes, patient care wipes, disposable medical consumables -

Hygiene and personal care

Baby wipes, facial wipes, cosmetic removal pads -

Household and industrial cleaning

Multipurpose wipes, surface cleaning cloths, oil-absorbent wipes -

Disposable protective products

Linings for protective clothing, hygiene layers, absorbent components

Its versatility allows manufacturers to tailor fiber ratios, basis weight, and finishing treatments according to end-use requirements.

Sustainability Considerations for European Buyers

In Europe, environmental compliance and material transparency are increasingly important. Woodpulp spunlace nonwoven fabric aligns well with these expectations because:

-

Wood pulp is derived from renewable forestry sources

-

Production uses water entanglement instead of chemical binders

-

Can be designed to meet biodegradable or flushable standards, depending on formulation

For buyers supplying EU markets, confirming raw material traceability, compliance with REACH, and disposability performance is essential during supplier evaluation.

What to Look for When Sourcing Woodpulp Spunlace Fabric

When evaluating manufacturers or factories, B2B buyers typically focus on the following criteria:

-

Fiber composition and ratio stability

-

Basis weight consistency across batches

-

Absorbency and tensile strength test data

-

Production scale and lead time reliability

-

Customization capabilities for rolls, sheets, or jumbo sizes

A reliable supplier should be able to provide technical specifications, testing reports, and application guidance based on your target market.

Final Thoughts

Woodpulp spunlace nonwoven fabric continues to gain popularity due to its balance of performance, comfort, and sustainability. For manufacturers and distributors serving medical, hygiene, and cleaning markets, it offers a flexible solution that meets both functional and regulatory demands.

As buyer searches become more specific, understanding the material’s properties and sourcing considerations can significantly improve product positioning and purchasing efficiency.

Post time: Feb-05-2026