1. What Is a Protective Suit and Why It Matters

Protective suits, also known as disposable coveralls or safety coveralls, are essential personal protective equipment used to prevent exposure to dust, chemicals, liquids, and contaminants. They are widely used in industrial manufacturing, chemical handling, construction, healthcare, laboratories, and cleaning operations.

For companies operating in high-risk environments, choosing the right protective suit is critical to ensure worker safety, reduce operational risk, and comply with international safety regulations.

2. Common Materials Used in Protective Suits

Different industries require different protective levels. The most common materials include:

a. Microporous Film Fabric (Type 5 6)

Known for strong particle and liquid resistance. Ideal for chemical plants, spray painting, and industrial maintenance.

• High barrier protection

• Lightweight and breathable

• Suitable for dust protection and light chemical splash

b. SMS Fabric

A combination of spunbond and meltblown layers.

• Good breathability

• Suitable for general industry and low-hazard environments

• Often used in medical and cleanroom settings

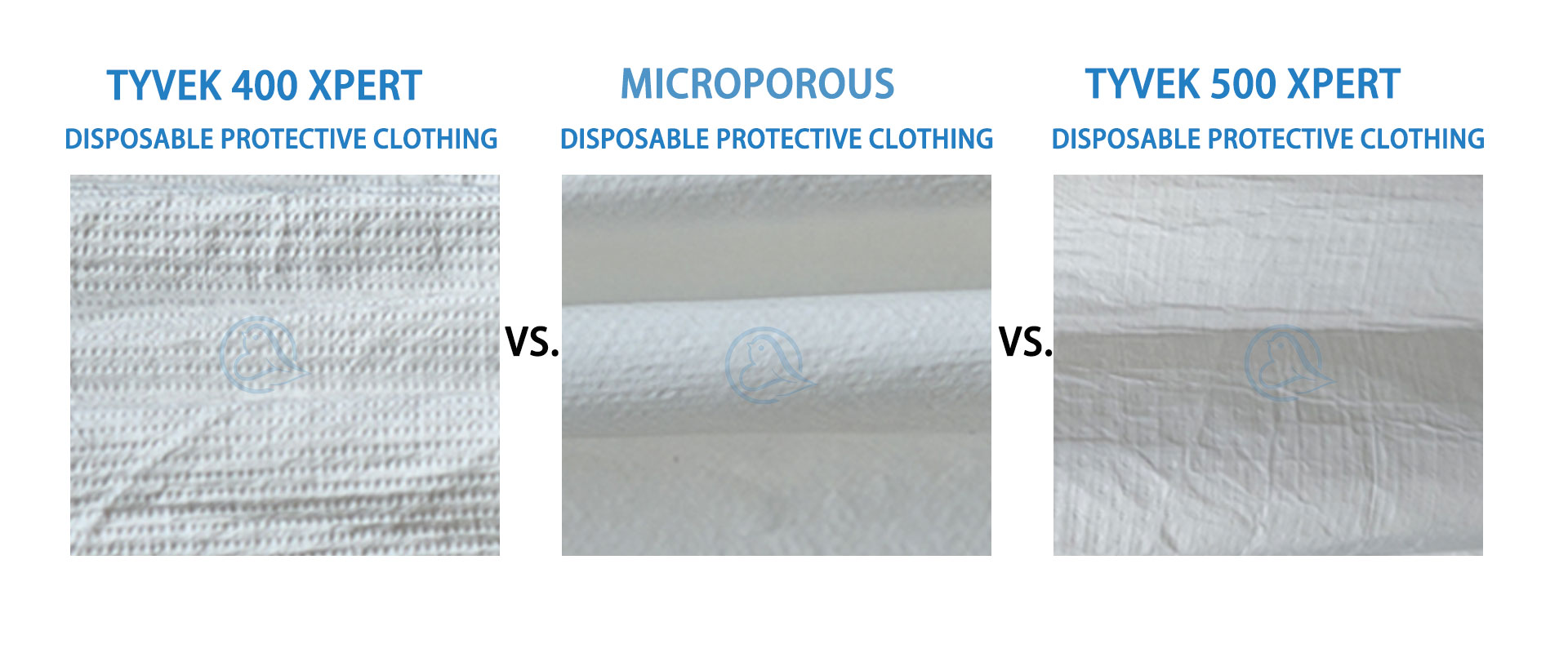

c. Tyvek-like High-Density Polyethylene Fabric

Premium protection material with strong durability.

• Excellent tear resistance

• High-grade particle protection

• Used in industrial painting, asbestos handling, and pharmaceutical plants

3. Certifications Buyers Should Look For

To meet international standards, a high-quality protective suit should comply with key certifications:

• EN 14126 for biological protection

• EN 13034 Type 6 for chemical splash resistance

• EN 13982 Type 5 for dry particle protection

• EN 14605 for liquid protection

• ISO 16603 / 16604 for synthetic blood penetration resistance

These certifications help buyers ensure the product is safe, reliable, and suitable for industrial usage, especially in Europe and the Middle East.

4. Industry Applications of Protective Suits

Protective suits are used across a wide range of sectors. The most common applications include:

Industrial and Construction

• Spray painting

• Grinding and cutting

• Cement and dust exposure

• Heavy-oil operations

Chemical and Petrochemical

• Chemical splash protection

• Solvent handling

• Reactor operations

• Pipeline maintenance

Healthcare and Laboratory

• Infectious droplets protection

• Laboratory sample handling

• Emergency response

Cleaning and Disinfection

• High-contact disinfection tasks

• Pesticide application

• Environmental sanitation

Companies using protective suits usually focus on barrier strength, comfort for long working hours, and cost-effective bulk purchasing.

5. Key Performance Features Buyers Value Most

When buyers search for protective suits online, they typically compare a few major performance features:

a. Barrier Protection

The suit should block dust, fine particles, chemicals, and liquid splashes.

Higher barrier levels are essential for chemical plants and industrial painting.

b. Breathability

Comfort matters for long shifts.

Microporous and SMS suits offer a good balance between protection and airflow.

c. Tear and Abrasion Resistance

Durable materials prevent ripping during bending, stretching, or movement.

d. Fit and Design

Three-dimensional tailoring, elastic cuffs, and sealed seams improve both safety and comfort.

e. Customization and OEM Capability

Large buyers often require custom printing, color options, or packaging flexibility.

6. How to Choose a Reliable Protective Suit Supplier

When evaluating suppliers, companies should consider:

Production Capacity

Large buyers need stable output and fast lead times.

A factory with multiple production lines can ensure steady supply.

Quality Control System

Look for suppliers with complete testing capabilities and compliance with ISO standards.

Global Export Experience

Suppliers with long-term partnerships in Europe, the Middle East, and South America usually understand local certification and documentation requirements.

OEM and Custom Services

Important for brands, distributors, and wholesalers.

7. Conclusion

Protective suits play a vital role in ensuring worker safety in highly demanding environments. By understanding materials, certifications, performance features, and applications, buyers can make more informed decisions and choose a reliable supplier that offers both safety and consistency.

If your goal is to source high-quality protective suits with strong performance across multiple industries, choosing a certified and experienced manufacturer is the key to long-term safety and compliance.

Post time: Dec-04-2025