As sustainability becomes a core focus across the hygiene and personal care industries, flushable spunlace nonwoven fabric is gaining increasing attention. Consumers, brands, and regulators are all demanding materials that deliver performance while reducing environmental impact. Flushable spunlace fabric responds directly to this shift.

Designed to disperse in water after disposal, this advanced nonwoven material plays a critical role in the development of modern flushable wipes and wet toilet tissue.

Understanding Flushable Spunlace Nonwoven Fabric

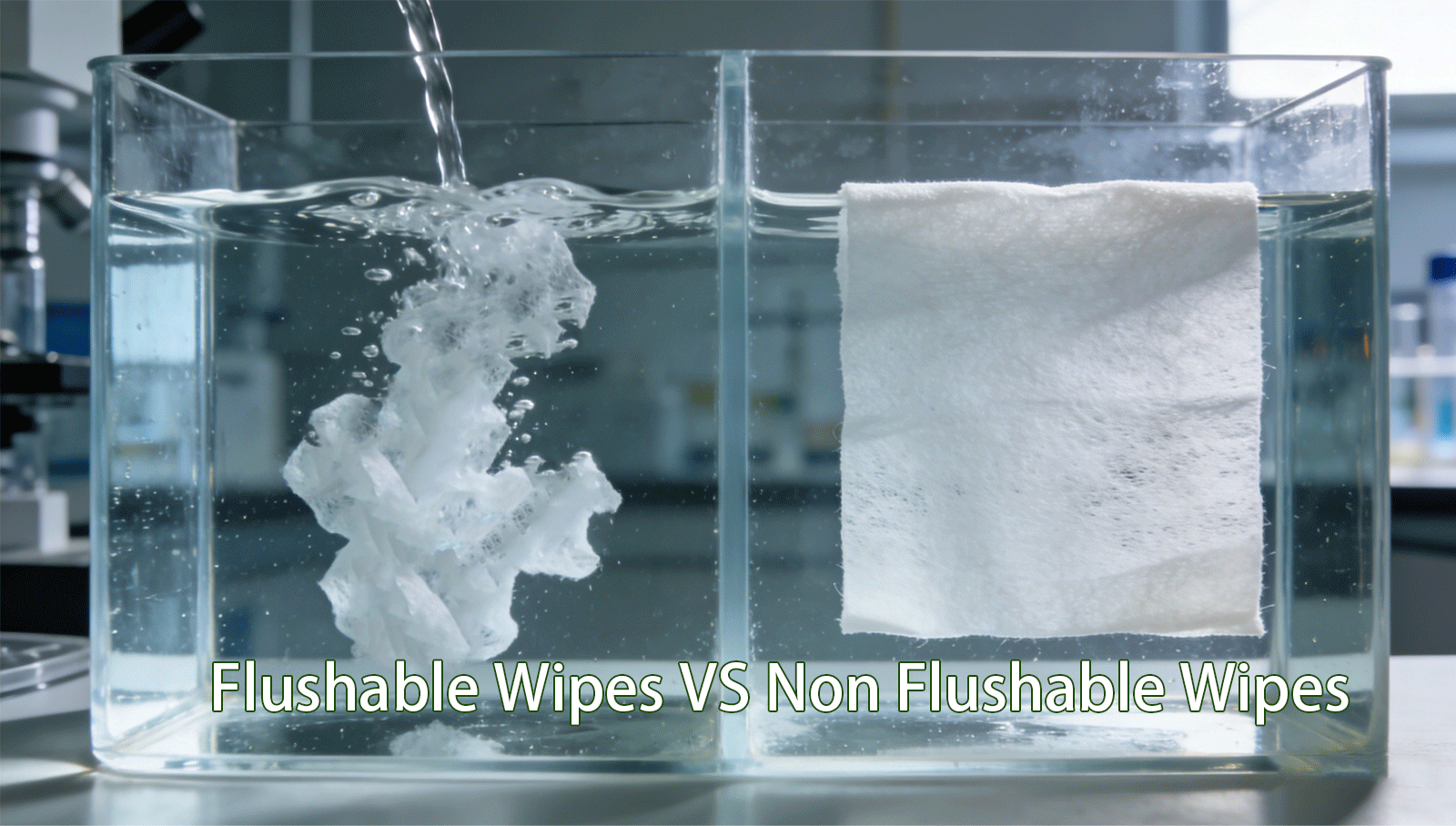

Flushable spunlace nonwoven fabric is manufactured through a hydroentanglement process, where high-pressure water jets bond fibers together without the use of chemical binders. What makes it “flushable” is its ability to lose structural integrity when exposed to water movement in sewage systems.

Through precise control of fiber composition and fabric structure, the material remains strong during use but disperses efficiently after flushing. This balance is essential for meeting both consumer expectations and wastewater system requirements.

Why Flushability Has Become a Key Market Demand

Search trends related to flushable wipes, plastic-free wipes, and biodegradable hygiene products have grown steadily in recent years. At the same time, concerns about sewer blockages caused by non-dispersible wipes have pushed the industry toward more responsible material solutions.

Flushable spunlace nonwoven fabric addresses these challenges by supporting safer disposal behavior while maintaining hygiene performance.

Core Benefits of Flushable Spunlace Fabric

Reliable Performance During Use

Despite its dispersible design, flushable spunlace fabric provides sufficient wet strength for effective wiping and cleaning.

Rapid Dispersion After Flushing

Once flushed, the fabric is engineered to break apart under mild mechanical action, helping to reduce clogging risks.

Soft and Skin-Friendly Feel

The spunlace process creates a smooth, cloth-like texture suitable for sensitive skin applications such as wet toilet paper and personal hygiene wipes.

Support for Sustainability Goals

Flushable spunlace fabrics are typically developed with high cellulose content and reduced plastic fibers, aligning with global sustainability initiatives.

Common Applications in Hygiene Products

Flushable spunlace nonwoven fabric is widely used in:

-

Flushable wet wipes

-

Wet toilet tissue

-

Personal hygiene wipes

-

Feminine care products

-

Medical and healthcare wipes

Its versatility makes it a preferred substrate for brands developing next-generation hygiene solutions.

How Flushable Spunlace Performance Is Engineered

Achieving proper flushability requires careful control of several technical factors:

-

Fiber type and blending ratio

-

Fabric basis weight (GSM)

-

Hydroentanglement pressure

-

Web structure and surface design

Optimizing these parameters ensures the fabric meets performance needs without compromising dispersibility.

Industry Outlook: Where the Market Is Headed

With tightening environmental regulations and growing consumer awareness, flushable materials are expected to see continued growth. Brands are increasingly working with specialized nonwoven manufacturers to develop customized flushable solutions that meet both regional standards and product-specific requirements.

Flushable spunlace nonwoven fabric is no longer a niche material—it is becoming a standard expectation in many hygiene categories.

Flushable spunlace nonwoven fabric represents a practical and forward-looking solution for the hygiene industry. By combining functionality, comfort, and responsible disposal performance, it supports the transition toward more sustainable personal care products.

For brands and manufacturers looking to stay competitive in the evolving global market, understanding and adopting flushable spunlace technology is a crucial step.

If you are exploring sustainable and flushable nonwoven solutions for hygiene products, understanding the right material structure and performance requirements is the first step toward successful product development.

Post time: Jan-08-2026