Meta Title: Flushable Nonwoven Fabric for Wipes– Standards, Composition, and Market Trends

Meta Description: Discover what makes a nonwoven truly flushable. Learn about materials, GD4/IWSFG standards, EU/US regulations, and supplier tips for bulk buyers.

What Is Flushable Nonwoven?

Why Testing Matters: GD4 and IWSFG

The term “flushable” is not universal. In the EU and US markets, the most recognized assessments are the GD4 Guidelines (developed by INDA and EDANA) and the IWSFG test methods. These simulate household plumbing and municipal wastewater conditions to evaluate whether wipes disperse quickly enough to prevent blockages.

For importers and OEM brands, requesting up-to-date GD4 or IWSFG test reports from suppliers is essential to validate product claims and avoid compliance risks.

Market & Regulatory Trends in Europe and the US

-

Europe: The UK and EU authorities have increased scrutiny of wipes containing plastics. Policies encourage clear labeling and, in some cases, propose restrictions on wipes that are not fully biodegradable.

-

United States: Flushability claims face growing consumer awareness and retailer requirements. Brands that cannot show evidence of GD4 or IWSFG compliance risk losing shelf presence.

-

Buyer Demand: Recent online search trends reveal high interest in “biodegradable flushable wipes,” “GD4 tested wipes,” and “plastic-free nonwoven fabric.” This shows that sustainability and compliance are now purchase drivers.

Key Considerations for Buyers

-

Composition Transparency – Request the exact ratio of pulp, viscose, and polyester. A higher natural fiber percentage generally improves dispersibility.

-

Accredited Testing – Ensure suppliers provide GD4/IWSFG lab reports tied to batch numbers.

-

Packaging & Labeling – Products should include clear disposal instructions, aligned with EU/UK guidelines.

-

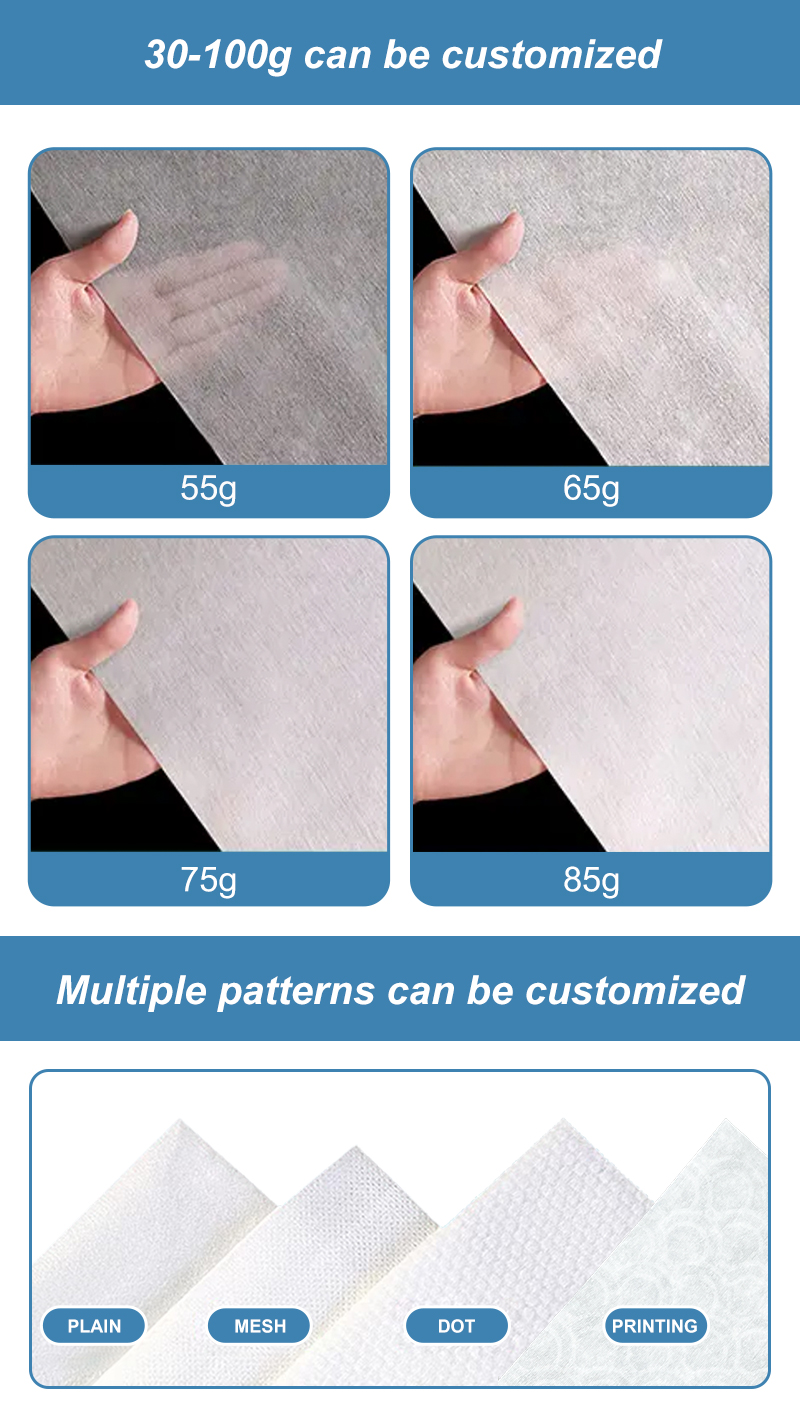

Customization Options – GSM, embossing, and fiber blends can be tailored to balance wet strength and dispersibility.

Conclusion

Flushable nonwoven is more than a marketing claim — it is a technical standard that buyers in Europe and the United States increasingly expect. By focusing on tested compliance, material composition, and regulatory awareness, businesses can secure reliable supply chains and meet consumer demand for environmentally responsible wipes.

For inquiries, partnerships, or bulk orders, please contact us at lita@fjxmmx.com.

Post time: Sep-29-2025