Why FFP3 Masks Matter in High-Risk Industrial Environments

In many industrial sectors, airborne hazards are not limited to visible dust. Fine particles, toxic powders, chemical aerosols and hazardous industrial by-products pose serious risks to workers’ respiratory health.

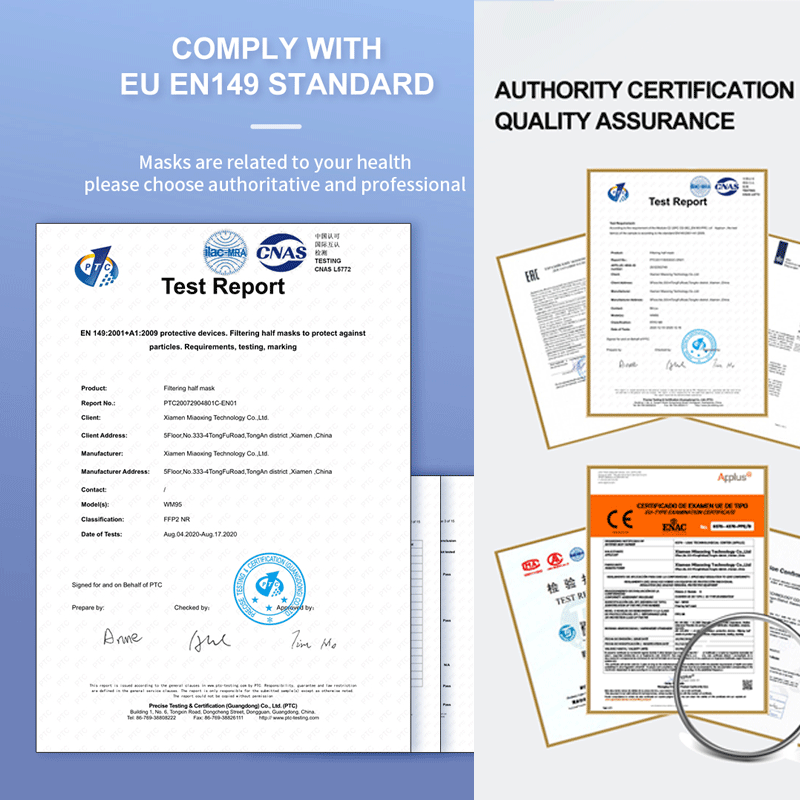

For such conditions, FFP3 disposable masks are designed to provide the highest level of particle filtration under the EN 149 standard.

For procurement managers and industrial buyers, choosing the right FFP3 mask is not only about protection performance, but also about regulatory compliance, workplace suitability and supply reliability.

EN 149 Compliance: What Industrial Buyers Should Check

FFP3 masks sold in the European market must comply with EN 149:2001+A1:2009. From a purchasing perspective, key compliance indicators include:

-

1.Filtration efficiency of at least 99%

-

2.Inward leakage strictly controlled under testing conditions

-

3.CE marking with a notified body number

-

4.Clear labeling on packaging and product documentation

For industrial procurement, compliance verification helps reduce legal risk and ensures masks can be used in regulated work environments such as chemical plants, mining operations and heavy manufacturing facilities.

Typical Industrial Applications of FFP3 Disposable Masks

FFP3 masks are commonly used in workplaces where exposure levels exceed medium-risk thresholds. Typical applications include:

-

1.Chemical processing and handling of hazardous powders

-

2.Mining, quarrying and mineral processing

-

3.Metal smelting, grinding and surface treatment

-

4.Industrial demolition and asbestos-related operations

-

5.Pharmaceutical and fine chemical manufacturing

In these environments, standard dust masks or lower-grade respirators may not provide sufficient protection.

Key Selection Criteria for Industrial FFP3 Masks

When sourcing FFP3 disposable masks for industrial use, buyers usually focus on more than filtration performance alone. Important selection factors include:

1. Fit and Sealing Performance

A secure fit reduces inward leakage and improves real-world protection. Adjustable nose clips and strong elastic headbands are commonly preferred for industrial use.

2. Breathing Resistance

Low breathing resistance improves comfort during long shifts, helping workers maintain compliance in demanding environments.

3. Valve or Non-Valve Design

Valved FFP3 masks are often chosen for high-temperature or physically intensive work, as they reduce heat and moisture buildup.

4. Bulk Supply and Consistency

Industrial buyers typically require stable batch quality, consistent specifications and long-term supply capacity.

Common Procurement Mistakes to Avoid

Industrial buyers sometimes encounter issues when sourcing FFP3 masks. Common mistakes include:

-

Relying solely on price without verifying certification

-

Confusing FFP3 masks with general-purpose industrial dust masks

-

Ignoring fit and comfort requirements for long-term use

-

Choosing suppliers without documented testing or quality control

Avoiding these pitfalls helps ensure both safety compliance and cost efficiency.

Why FFP3 Masks Are a Long-Term Industrial Safety Investment

From a procurement standpoint, FFP3 disposable masks are not just consumables. They are a key part of workplace safety systems.

By selecting compliant products from experienced manufacturers, industrial buyers can improve worker protection, reduce operational risk and meet regulatory requirements across multiple applications.

Final Thoughts for Industrial Buyers

As industrial environments become more regulated and exposure risks more complex, demand for high-performance respiratory protection continues to grow.

FFP3 disposable masks remain a critical solution for high-risk workplaces where reliable particle filtration and compliance are essential.

Post time: Jan-20-2026