Disposable protective clothing plays a critical role in modern industrial safety, infection control, and contamination prevention. As global regulations tighten and workplace safety standards improve, the demand for high-quality disposable protective suits continues to grow—especially across Europe and the Middle East.

If you are sourcing disposable protective clothing for medical, industrial, or cleanroom use, this guide will help you understand materials, standards, applications, and key purchasing considerations.

What Is Disposable Protective Clothing?

Disposable protective clothing (also called disposable coveralls or protective suits) is single-use personal protective equipment (PPE) designed to protect the wearer from hazardous particles, light chemical splashes, biological agents, and workplace contaminants.

Unlike reusable garments, disposable suits are:

-

Lightweight

-

Breathable (depending on material)

-

Cost-effective for bulk procurement

-

Designed to reduce cross-contamination risks

They are widely used in healthcare, laboratories, pharmaceuticals, food processing, chemical handling, construction, and cleanroom environments.

Why Demand for Disposable Protective Suits Is Growing

Recent Google search trends show consistent global interest in terms such as:

-

Disposable protective suit

-

PPE protective clothing

-

Chemical resistant coverall

-

Disposable medical protective clothing

-

Type 5 Type 6 coverall

The reasons behind this demand include:

1. Stricter Workplace Safety Regulations

European and Middle Eastern buyers increasingly require compliance with EN and ISO standards.

2. Increased Infection Control Awareness

Post-pandemic procurement strategies now prioritize reliable PPE suppliers and certified products.

3. Industrial Expansion

Chemical plants, oil & gas projects, and pharmaceutical manufacturing facilities are increasing PPE consumption.

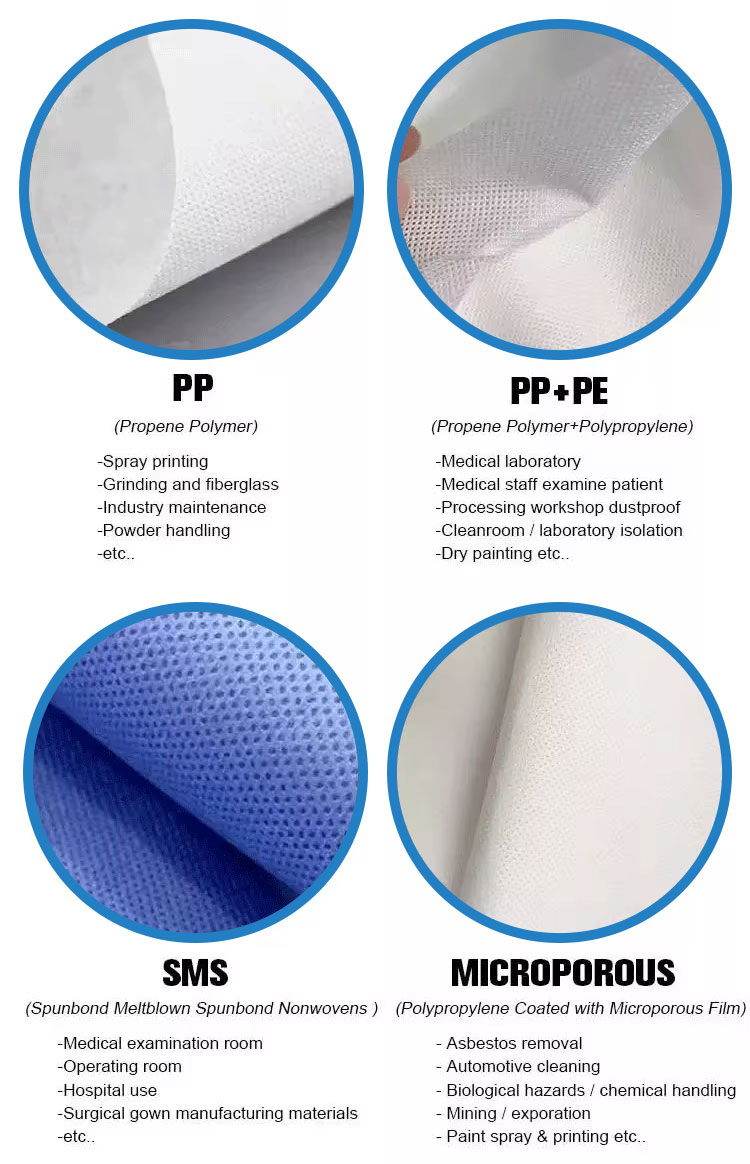

Common Materials Used in Disposable Protective Clothing

Material selection directly affects protection level, breathability, and comfort.

1. Polypropylene (PP)

-

Lightweight

-

Cost-effective

-

Suitable for low-risk environments

2. Microporous Film Laminated Fabric

-

Higher barrier performance

-

Resistant to liquid splashes

-

Ideal for industrial and laboratory use

3. SMS (Spunbond-Meltblown-Spunbond)

-

Good filtration efficiency

-

Balanced breathability and protection

-

Popular in medical applications

For B2B buyers, understanding fabric composition is essential when comparing supplier quotations.

European Protection Standards Explained

If your target market includes Europe, compliance is critical. The most searched protective categories include:

-

Type 5 – Protection against airborne solid particles

-

Type 6 – Limited protection against light liquid sprays

Buyers often search for:

-

EN 14126 protective clothing

-

CE certified disposable coveralls

-

PPE Category III protective suit

Including certification details on product pages improves both buyer trust and Google ranking relevance.

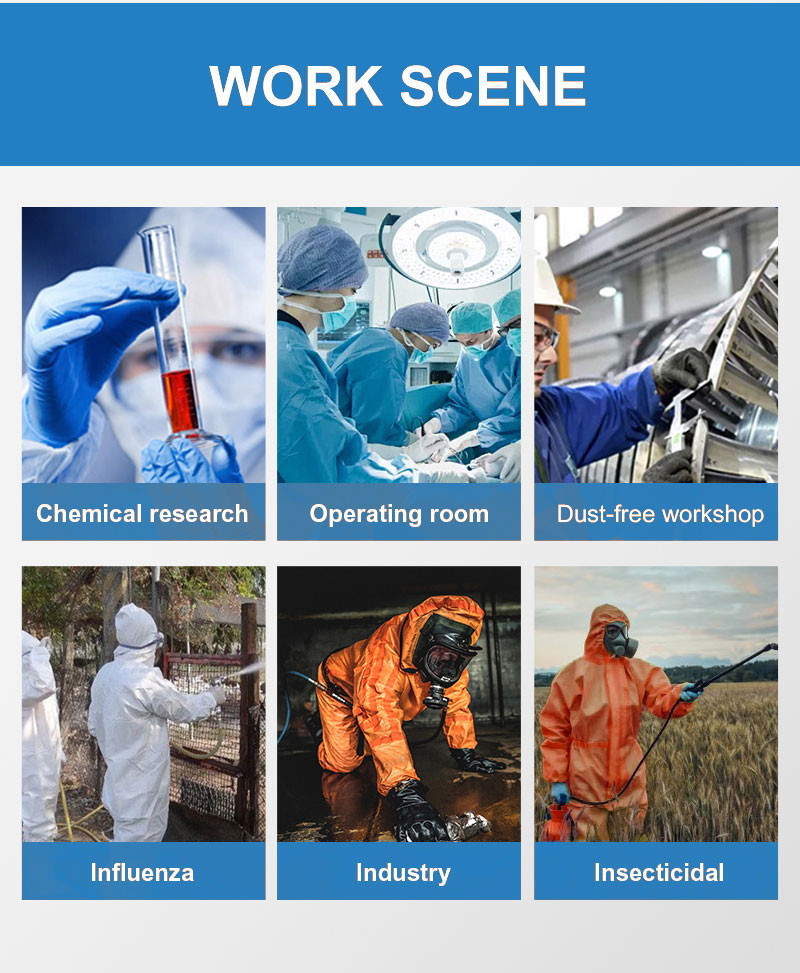

Key Industries Using Disposable Protective Clothing

Healthcare & Medical

Used for infection control in hospitals, clinics, and laboratories.

Chemical & Industrial Manufacturing

Protects workers from dust, fine particles, and mild chemical splashes.

Pharmaceutical & Cleanroom

Prevents product contamination during sterile production processes.

Food Processing

Maintains hygiene compliance and reduces cross-contamination risk.

How to Choose the Right Disposable Protective Suit

When evaluating suppliers, consider the following:

-

Protection level (Type 5 / Type 6 or higher)

-

Fabric weight (commonly 45gsm–65gsm)

-

Breathability vs. barrier performance

-

Certification and test reports

-

Production capacity and delivery time

-

OEM/Private label support

For bulk buyers, factory production scale and quality control systems are often more important than price alone.

FAQ – Disposable Protective Clothing

Q1: What is the difference between Type 5 and Type 6 protective suits?

Type 5 protects against airborne particles, while Type 6 offers limited protection against light liquid sprays.

Q2: Are disposable protective suits breathable?

Yes, depending on fabric structure. Microporous laminated materials offer better barrier performance, while SMS provides better breathability.

Q3: Can disposable protective clothing be reused?

No. They are designed for single use to prevent contamination risks.

Q4: What certifications are required for Europe?

CE marking and compliance with relevant EN standards are typically required.

Conclusion

Disposable protective clothing remains an essential component of modern workplace safety strategies. With increasing global demand and stricter compliance requirements, selecting the right material, protection level, and certified supplier is critical for long-term procurement success.

Post time: Feb-13-2026