Market Overview

The global demand for cleanroom paper has been growing steadily in recent years. According to multiple industry reports, the cleanroom consumables market, including specialty papers, is projected to grow at a CAGR of 5–7% over the next few years. This growth is driven by industries such as semiconductors, biotechnology, pharmaceuticals, and medical device manufacturing, where contamination control is essential. Buyers are increasingly searching for industrial paper, non woven paper, and low-lint documentation paper that can meet strict ISO cleanroom standards.

Why Choose Cleanroom Paper?

Ordinary office paper is not suitable for controlled environments because it sheds fibers, generates particles, and may release chemical residues that can contaminate sensitive equipment or processes. Cleanroom paper is engineered to reduce particle generation, resist static charge, and maintain stability under cleanroom conditions.

Key advantages include:

-

Low lint and low particle release, reducing the risk of contamination.

-

Durable wet and dry strength, allowing usage in both humid and sterilized environments.

-

Compatibility with printers and copiers, ensuring smooth documentation without shedding.

-

Chemical resistance, minimizing extractables and supporting use with solvents or disinfectants.

Choosing cleanroom paper helps industries meet regulatory standards such as ISO 14644, GMP, and FDA guidelines, making it essential for any facility that values quality control and product safety.

Material Composition

Cleanroom paper is manufactured using a blend of 55% wood pulp and 45% polyester fibers, which provides both absorbency and durability. The wood pulp ensures smooth printing and writing performance, while polyester enhances wet strength, tear resistance, and dimensional stability. This combination minimizes particle release and ensures the paper remains stable under both dry and humid conditions.

In addition, cleanroom paper is often available in white and blue colors, which help differentiate applications or identify cleanroom zones. Some specialized versions are designed to be autoclavable, allowing them to withstand sterilization processes without deformation or chemical breakdown.

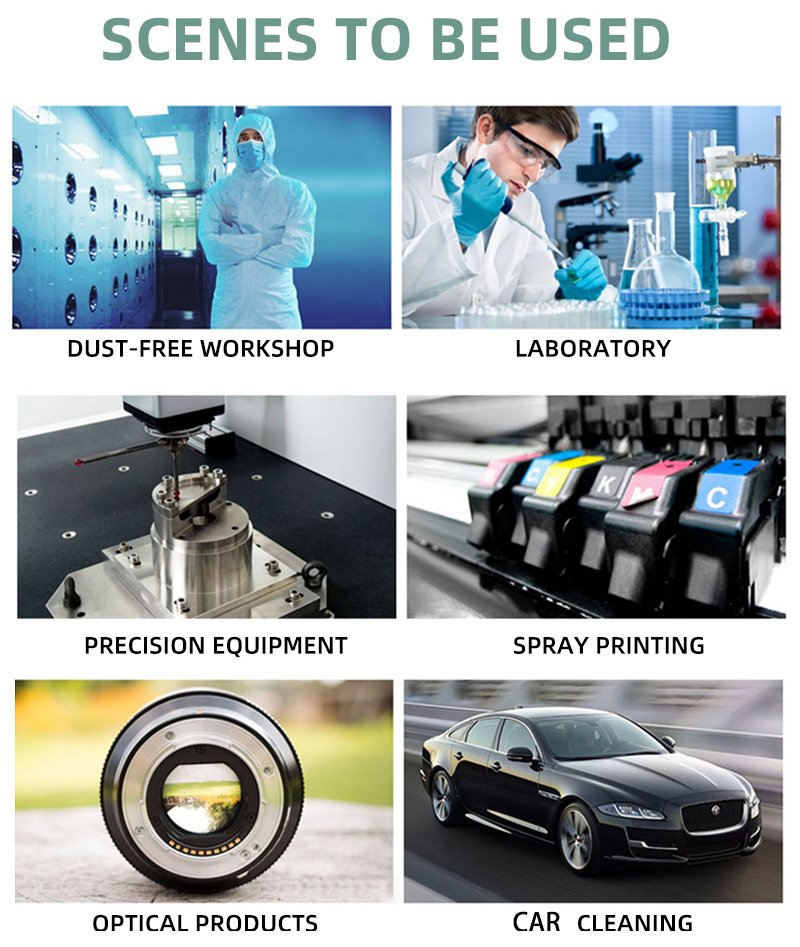

Applications of Cleanroom Paper

The versatility of cleanroom paper makes it suitable for a wide range of industries:

-

Semiconductor and Electronics: Used for recording sensitive data, printing process documents, and labeling equipment, where even small particle contamination can affect product yield.

-

Pharmaceutical and Biotechnology: Applied for batch records, research documentation, and sterilizable labeling inside controlled environments.

-

Medical Device Manufacturing: Provides reliable documentation paper that resists shedding fibers, ensuring compliance with regulatory standards.

-

Cleanroom Documentation: Commonly used for SOPs, logbooks, forms, and labels within ISO-classified environments.

-

Industrial Applications: As a type of industrial paper, it is used for protective wrapping, packaging, and other contamination-sensitive processes.

How to Choose the Right GSM for Different Applications

The GSM (grams per square meter) of cleanroom paper determines its thickness, strength, and absorbency. Selecting the right weight ensures both cost-effectiveness and functionality.

-

56–60gsm: Best for everyday documentation such as SOPs, logbooks, and printing forms. Lightweight yet durable enough for cleanroom use.

-

70–80gsm: Ideal for technical documents, drawings, and reports that require extra durability and resistance to tearing.

-

90–100gsm: Suitable for packaging, wrapping, or protective covers in cleanroom environments, where stronger and thicker paper is required.

-

Custom GSM above 100gsm: Designed for specialized uses such as protective layering in electronic or medical device assembly lines.

By choosing the appropriate GSM, businesses can balance cost, performance, and regulatory compliance according to their operational needs.

Customization Options

To meet diverse customer needs, manufacturers now provide custom cleanroom paper solutions. Options include:

-

Different GSM levels to match specific industry applications.

-

Sheet or roll formats, depending on documentation or packaging requirements.

-

Color variations (white, blue, or customized colors for zone identification).

-

Pre-printed lines, logos, or batch codes to improve traceability and support quality management.

-

Eco-friendly alternatives, such as FSC-certified pulp or recycled polyester blends, for companies with sustainability goals.

Conclusion

With expanding applications in electronics, pharmaceuticals, medical devices, and industrial sectors, the demand for cleanroom paper is expected to rise steadily. Its unique wood pulp and polyester blend makes it highly functional in environments where contamination control is critical. For buyers looking for reliable, customizable, and compliant cleanroom paper, working with a manufacturer that supports tailored specifications ensures better performance and long-term value.

For inquiries about cleanroom paper solutions, please contact us at lita@fjxmmx.com

Post time: Sep-12-2025